Ultimate Guide for Industrial & Commercial Cooling

Industrial operations and commercial facilities rely on specialized cooling systems to maintain efficiency. Whether you need precise process cooling for manufacturing or climate control via HVAC chillers, understanding the differences between these systems is critical. This guide compares process chillers and HVAC chillers, their applications, and how to choose the right chiller system for your needs.

What Is a Chiller? How Do Industrial Chillers Work?

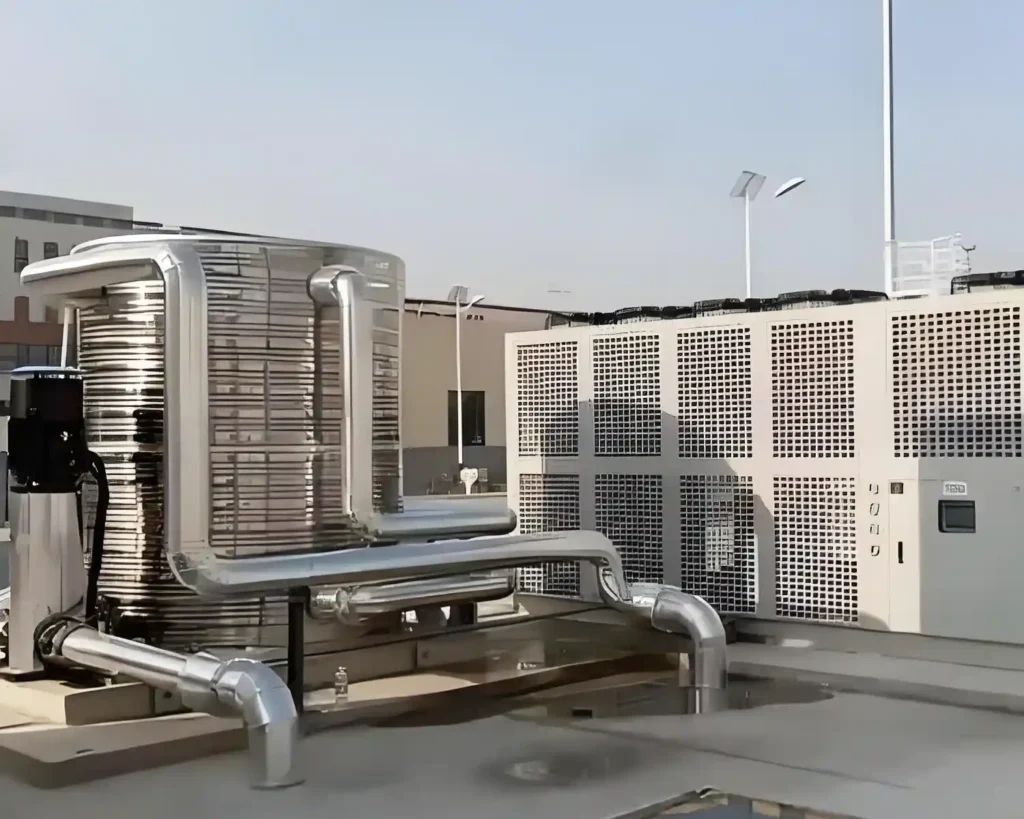

A chiller is a refrigeration device that removes heat using a chiller unit with water or refrigerant. Key components include compressors, evaporators, and condensers.

- Process Chillers: Designed for direct equipment cooling (e.g., laser cutters, plastic injection molds) in industries like pharmaceuticals or food processing.

- HVAC Chillers: Regulate air temperature in buildings via chilled water systems, commonly used in offices, hospitals, and data centers.

Key Differences: Process Chiller vs. HVAC Chiller

1. Design & Functionality

| Feature | Process Chiller | HVAC Chiller |

|---|---|---|

| Cooling Method | Direct equipment cooling | Ambient air cooling |

| Redundancy | Dual-circuit design | Single-loop system |

| Precision | ±0.5°C with PID controllers | ±2°C basic thermostats |

| Typical Use Case | Industrial chillers for manufacturing | Commercial chillers for buildings |

Technical Insight: Vapor-compression chillers dominate industrial applications, while absorption chillers suit low-noise environments like hospitals.

2. Energy Efficiency & Operating Costs

- Process Chillers:

- Use inverter-driven compressors to save 25-30% energy vs. fixed-speed units.

- Ideal for 24/7 operations like process water chillers in breweries.

- HVAC Chillers:

- Peak efficiency in moderate climates; require chiller lift retrofits for extreme cold.

- Higher seasonal maintenance costs due to boiler chiller integration.

3. Industry Applications

- Process Chiller Applications:

✅ Plastics Cooling: Maintain mold temperatures in injection molding.

✅ Laser Cutting: Prevent overheating in metal fabrication.

✅ Pharmaceuticals: Precise cooling for reactor vessels.

✅ Data Centers: Backup chiller systems for server farms. - HVAC Chiller Applications:

✅ Office Buildings: Central chiller system in building setups.

✅ Hospitals: Sterile climate control with air conditioning chillers.

✅ Retail Spaces: Energy-efficient commercial chillers for malls.

Pro Tip: For temporary sites, consider chiller rentals or mobile chiller trailers.

4. Maintenance & Technical Support

- Process Chillers:

- Require quarterly checks by chiller technicians (refrigerant levels, pump alignment).

- Partner with suppliers offering chiller training courses for in-house teams.

- HVAC Chillers:

- Annual inspections focus on boilers and chillers integration.

- Emergency chiller replacement parts cost up to $15,000 (e.g., compressors).

5. Cost Comparison

| Expense | Process Chiller | HVAC Chiller |

|---|---|---|

| Initial Cost | $25,000 – $80,000 | $40,000 – $120,000+ |

| Energy Cost/Year | $8,000 – $15,000 | $12,000 – $25,000 |

| Maintenance Cost/Year | $2,000 – $5,000 | $3,000 – $8,000 |

Chiller Energy Savings & ROI Calculator

Chiller vs. AC Unit: Which Is Better?

While residential AC units suffice for homes, chiller systems outperform them in:

- Capacity: Chiller AC units cool large spaces (e.g., warehouses).

- Precision: Process chillers maintain ±0.5°C for labs.

- Durability: Industrial chillers withstand 24/7 operation.

For small businesses, chiller vs AC decisions hinge on upfront costs vs. long-term efficiency.

How to Choose a Chiller Supplier

- Certifications: Verify ASHRAE, ISO 9001, or NSF compliance.

- Customization: Opt for modular chiller systems (e.g., chiller tower add-ons).

- Warranty: Compare coverage periods (e.g., chiller carrier offers 5-year warranties).

Conclusion

Selecting between process chillers and HVAC chillers hinges on your industry, budget, and precision needs. For manufacturing, prioritize industrial chillers with dual-circuit reliability. For commercial spaces, HVAC chillers balance cost and performance.

Need Expert Advice?

Contact our chiller specialists today for a free consultation on chiller system design, rentals, or technician training.