Precision Chillers for Electronics Manufacturing

High-reliability chillers for semiconductor fabs, data centers, medical devices, and telecom. Ensure thermal stability, prevent overheating, and extend equipment lifespan.

Why Cooling is Critical in Electronics Manufacturing

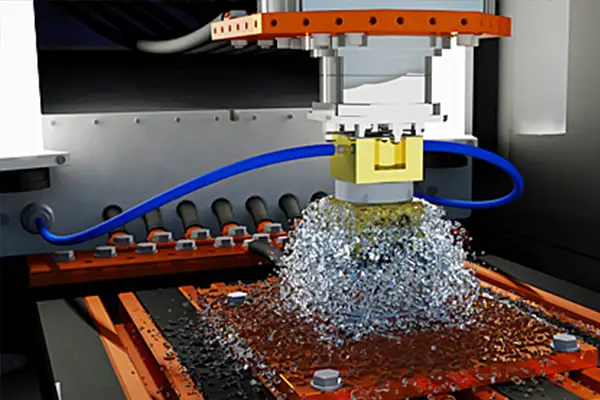

Heat generated during machining, cutting, and heavy-duty operations can lead to:

- Component degradation and failure.

- Reduced processing speeds and data loss.

- Inaccuracies in medical imaging and diagnostics.

Industrial chillers maintain precise temperatures for peak performance and long-term reliability.

Key Applications of Chillers in Electronics

1. Semiconductor Manufacturing

Cooling Needs: Lithography, etching, and wafer processing require ±0.1°C stability.

Heat from plasma etchers and chemical vapor deposition (CVD) chambers.

Chiller Solutions: Ultra-pure water chillers at 15–22°C for photoresist development.

Redundant systems for 24/7 wafer fabrication.

2. Data Center Cooling

Cooling Needs: High-density servers generate up to 30 kW per rack.

CPU/GPU liquid cooling for AI and cloud computing.

Chiller Solutions: Free cooling chillers (7–12°C) for energy-efficient hyperscale data centers.

Direct-to-chip liquid cooling with leak-proof quick-connect systems.

3. Medical Electronics

Cooling Needs: MRI superconducting magnets (cryogenic cooling at -269°C).

Laser systems for surgery and diagnostics.

Chiller Solutions: Closed-loop glycol chillers (-40°C) for MRI RF amplifiers.

Compact air-cooled units for portable medical devices.

4. Power Electronics & EVs

Cooling Needs: EV fast-charging stations and battery test systems.

IGBT cooling in solar/wind inverters.

Chiller Solutions: 25–35°C water-cooled systems with anti-corrosion coatings.

Modular chillers for scalable charging infrastructure.

5. Telecommunications

Cooling Needs: 5G base stations and edge computing nodes.

Fiber-optic amplifier cooling.

Chiller Solutions: Outdoor-rated chillers (-10°C to +45°C ambient) for telecom cabinets.

Low-noise systems for urban deployments.

Benefits of Our Electronics Chillers

✔️ Nano-Temperature Stability: ±0.1°C control for semiconductor lithography.

✔️ Medical Compliance: ISO 13485-certified systems for MRI and CT scanners.

✔️ Energy Efficiency: EC fans and variable-speed compressors reduce energy use by 40%.

✔️ Smart Monitoring: IoT integration for predictive maintenance and remote control.

Industries We Serve

Semiconductor Fabs: Etching, deposition, wafer testing.

Data Centers: Liquid cooling for AI/ML servers.

Medical OEMs: Imaging, lab equipment, laser systems.

EV & Renewable Energy: Battery testing, inverter cooling.

Telecom: 5G infrastructure, network hubs.

Why Choose Us?

- Industry-Specific Expertise: 10+ years serving anodizing and plating facilities.

- Custom Solutions: Tailored chiller configurations for unique process needs.

- 24/7 Support: Rapid response for minimal downtime.